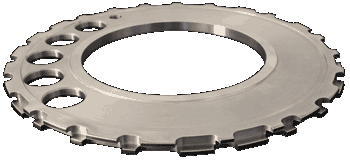

If you deal with late model engines, you, no doubt, have dealt with a Crankshaft Reluctor Ring. So what is a reluctor ring? It's a multi-toothed timing ring press-fit on a crankshaft which works with a magnetic sensor to identify crankshaft position. Quite the mouthful, huh?

If you deal with late model engines, you, no doubt, have dealt with a Crankshaft Reluctor Ring. So what is a reluctor ring? It's a multi-toothed timing ring press-fit on a crankshaft which works with a magnetic sensor to identify crankshaft position. Quite the mouthful, huh?

There are two common configurations of reluctor rings – 24 tooth and 58 tooth. They are generally two plates that are welded together, though Callies Crankshaft makes single-piece models (available through Goodson). Reluctor Rings are also called tone rings or timing plates.

In this article, we’re going to look at the procedure for removing and installing the reluctor ring using the Goodson Reluctor Ring Installation Tool (RRJ-350).

Let’s start with removal. It’s not as easy as it may sound since there isn’t a key or other registering device. Before beginning removal, make witness marks on both the reluctor wheel and the crankshaft rear flange. Proper position of the wheel is essential.

To avoid bending or distorting the reluctor wheel, DO NOT use a puller when removing it. We recommend heating the wheel with a torch to about 200ºF. Like all metal, the wheel will expand and you should be able to slip it off easily. Be sure to wear heat resistant gloves.

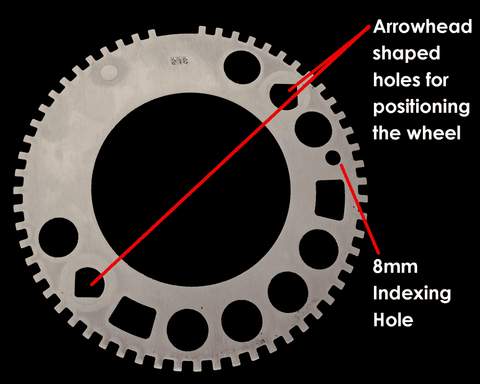

First, let‘s take a look at the tool and the reluctor ring in a little more detail.

The Reluctor Ring Jig is designed specifically to fit Generation III (LS1 and LS6) and Generation IV (LS2, LS3 and LS7) GM motors.

Now, let’s get the reluctor wheel installed.

Chamfer the entry edge of the reluctor ring to ease installation. Be sure that you have thoroughly deburred the edges. Any sharp edges may cause the reluctor ring to catch on the casting, making installation impossible.

Heat the reluctor ring to approximately 450ºF (232ºC) using a torch or in your cleaning oven. Remember, if you use a torch that you need to be very careful to apply the heat uniformly to ensure consistent expansion of the ring. Line up the 8mm indexing dowel with the 8mm indexing hole and slip the reluctor ring onto the jig. Now, slip the reluctor ring onto the crankshaft. In his Engine Professional article, Mike Mavrigian says, "I heated the the wheel's ID lip with a torch, slipped the wheel onto the Goodson jig, and the wheel slid onto the crank as easily as a rock drops into water."

A couple of final thoughts:

- DO NOT try to bang the reluctor ring into place; you'll only end up damaging it and having to start all over.

- Cold pressing the ring into place can easily warp it, leaving it useless.

As always, if you have any questions about this or any other technical topic, contact the Goodson Techxperts by phone (800-533-8010) or email.